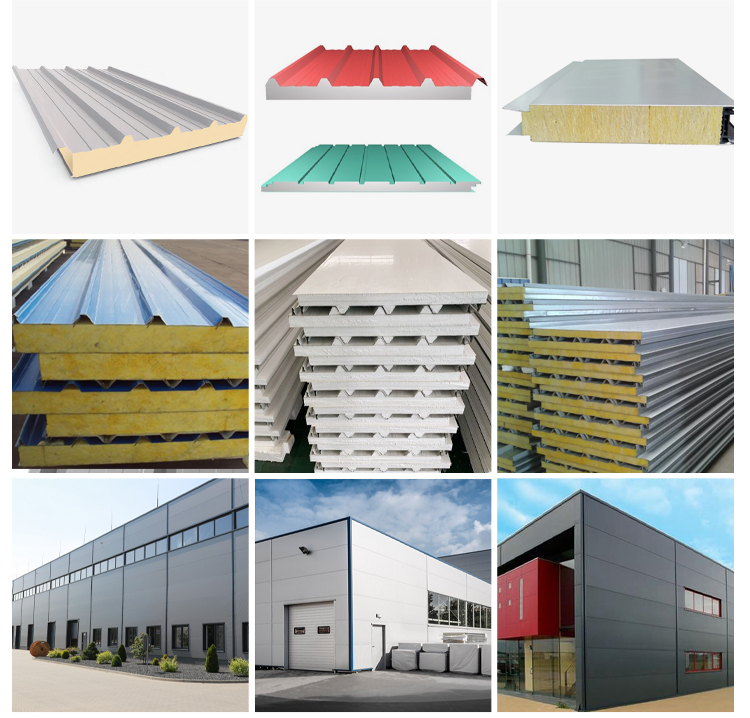

Discontinuous PU/PUR/PIR Sandwoch Panel Production Line

Product categories: PU/PUR/PIR (Sandwich) Panel Production Line

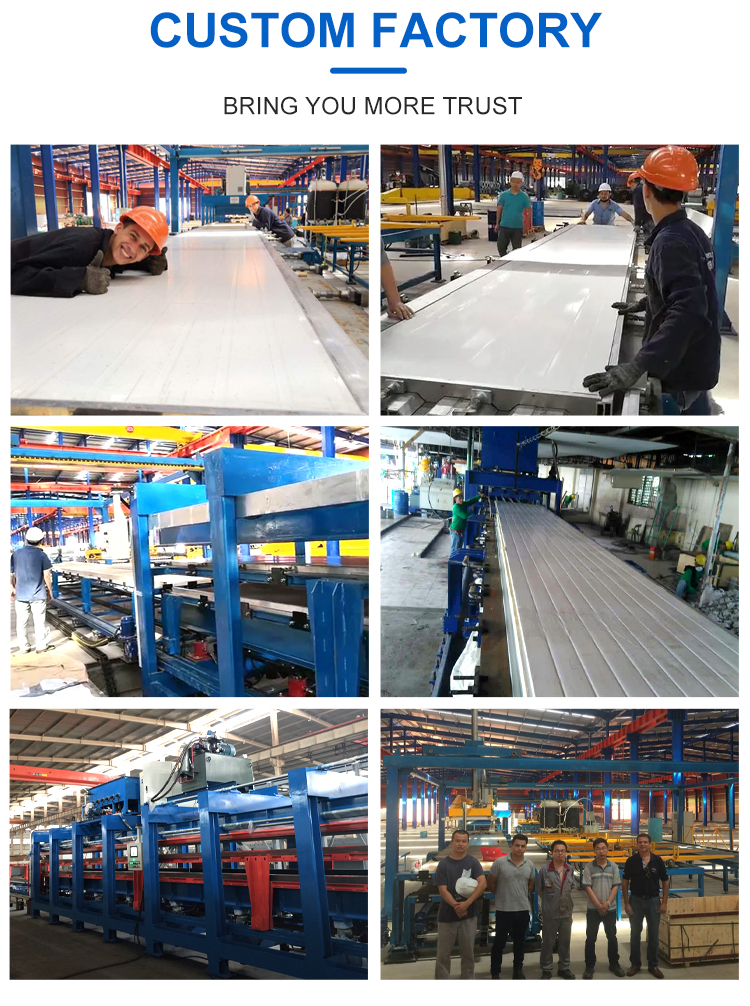

Product display: Continuous PU / PUR /PIR Sandwich Panel Production Line,PU andwich Panel Production Line,PU Production Line Supplier & Manufacturer in China

Product description: The whole system includes uncoiling system, film covering and cutting system, roll forming machine,preheating oven, high pressure foaming system, double belt conveyor, double belt heating device, cutting system, etc.

Machine Description

CHARACTERISTICS OF MAIN MACHINERY

1. Guangxing Discontinuous PU/PIR Sandwich Panel Production Line (10M ,2+2 ) is designed with leading Guangxing technology and leading European technology .

2. Guangxing machines are manufactured to ISO9001:2008 and CE standard .

3. The press machine adopts gantry lift-draw type, locates directly without any foundation. 2+2 type saves much time for panel preparation and discharge time which increase times of efficiency. At the same time, the high quality working tables offer the best ensure for good quality sandwich panel. Bidirectional trolley adopts separate float guide rails with some advantages like mutual noninterference, accurate location and easy operation.

Working process:

The multi-layer press system is composed by a main press machine and rail brackets mounted on both sides. Press machine includes upper and down two load-mold-boards . Each side rail bracket on the press also remains one load-mold-board . When production :

Step 1: Put upper and down steel sheets into the mold frame on the load-mold-boards ; seal the edge and coat mold-release agent ,etc.

Step 2: Two load-mold-boards enter the main press machine at the same time by driving force. Meanwhile , two load-mold-boards inner the press machine move out and stay on the rail bracket .

Step 3: Press machine closes. Inject PU/PIR raw material into each layer , at the same time , PU/PIR foaming and aging

Step 4: After 10-30 minutes (according to PU/PIR material and operation experience), lift the press, move the molding frame, then get the PU/PIR sandwich panel, Non-slip pedals, Electric control system, etc.

The main points of Guangxing Discontinuous PU/PIR Sandwich Panel Production Line ( 10M , 2+2 ):

●Components High Pressure Polyurethane Foaming Machine

●Product size :10000 x 1000 mm

●Panel thickness: 40-150mm (Adjustable)

●Capacity : Around 600-800m2/day(as 8 hours), around 150,000-200,000m2 /year (as 250 work days).

●Workers : The producers of single shift need to be 5-6 workers for each line

●Workshop : Production line size at least L 34 x W 38 x H 4 mtrs . Require workshop larger than this size .